Fundamental principles to good business

“The quality of an organisation is the degree to which the inherent characteristics of an organisation fulfil the needs and expectations of its customers and other interested parties in order to achieve its sustained success (what is relevant to this success is determined by the organisation).” ISO 9000:2015

Quality management should be more than just ticking a box

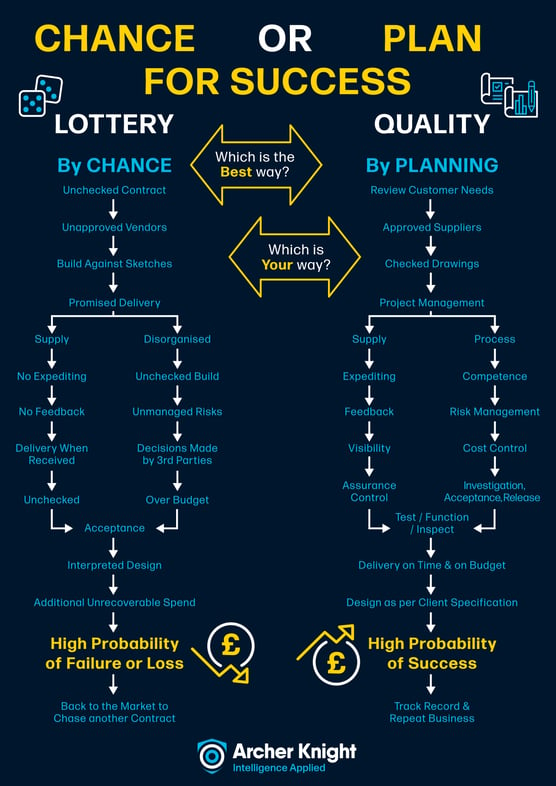

Quality management is vital to an organisation’s success – a business with a real commitment to quality and the correct tools in place, is better placed to do well than one which leaves it to chance.

All too often though, I’ve found the way company’s approach this to be something of a lottery. Quality management can be treated as a ‘tick-box exercise’ for the top-management tier (creating additional work elsewhere to correct the ‘faults’); other times policies and strategy plans are known only to an elite few within the business.

Personally, I’d like to see the same kudos and prominence given to quality management as there is on safety. After all – and I say this as a Chartered Safety Practitioner – get the quality right and safety should be an automatic bolt-on. The converse is not always necessarily true.

The principles of quality management have been refined over the years to meet new standards, (ISO 9000, 9001) there are seven steps to ensuring you get it right:

1) Focus on customers

Companies need to meet and exceed the end-customers’ expectations. This also means understanding the needs and expectations of all parties involved in delivering a product or service. Internal ‘customers’ (such as the recipients of process deliverables) are often not included or not given as much focus as the end client.

It reminds me of the classic ‘tree swing’ cartoon, in circulation since I started working in the aviation industry 50 years ago. It presents a range of outlandish solutions for a swing hung from a tree, when all the customer needed was a tyre tied to a rope. I still find it funny but it’s sadly still also a fairly accurate parody of today’s business world.

2) Showing leadership

Good leaders are visible, open, approachable and communicate well. They provide direction and are central to fostering culture. The converse is also true. Poor leaders give poor direction and foster cultures which leads to expensive uncontrolled business risks. We’ve seen this in high-profile examples, such as BP and the Deepwater Horizon oil spill and Volkswagen emissions scandal.

The current Quality Standard ISO 9004:2018 puts top management squarely in the crosshairs, requiring demonstration of leadership by ‘defining and maintaining the organisation’s objectives based on its policies and strategy’. In my experience, quality objectives have normally been set by the quality assurance (QA) manager around the previous year’s non-conformance figures and customer complaints – competitive factors in achieving the business plan don’t generally get included.

3) Company-wide engagement

Competent, engaged, empowered and motivated workforces make the difference between whether a company is merely hoping for success, or planning against failure. The probability of success is greatly increased when it’s the latter. Effective engagement requires communication – meaningful, timely and continual. A company which engages well with its teams will include a feedback mechanism which is tailored to the differing needs of its recipients.

4) Process, process, process

Having in place a series of interlinked processes that optimises performance is essential. Every process should have an initiator, objective(s), resources and deliverable(s). This deliverable then becomes the initiator to the next process, considering the needs and expectations of interested parties. Just like safety management, the internal process mechanism for quality can be identified using the four Cs: communication, cooperation, competence and control of risk. Process management should have individuals who are accountable and have ownership of the processes at each stage. If they don’t, policies and strategies tend not to be supported and you run the risk of the processes driving the business, not the other way around.

5) Keep improving

In today’s fast-moving industry, as we seek to create leaner, more-efficient businesses, no one can afford to stand still and rest on their laurels. Improvement objectives and targets should not just be paid lip service but be continually monitored, audited and updated.

How often are monthly or periodic reports on quality statistics submitted with no feedback, questions or comment on their success or failure? Have the most recent objectives been set with little or no recognition of the previous year’s measures? This tells me that what is being measured has no relevance to the policies and strategy set by top management.

Internal auditing is an effective tool for determining the level of conformity of its management system to its selected criteria, as well as identifying areas of opportunity. However, I have seldom seen the findings of these audits discussed at senior level or given the same focus as second or third-party audits.

6) Get the evidence

Decisions should always be based on analysis and evaluation of data and information. Decision making often involves multiple inputs and interpretations. Facts and data analysis lead to greater objectivity and confidence for businesses as they balance evidence with experience and intuition to make the correct choices.

7) Get your relationships right

Relationship management with suppliers and partner networks is another important principle. Determine which interested parties are critical to supporting your operations and manage according to the level and priority of criticality. To do this your business needs to determine what constitutes critical and identify how the relationship will be managed for your benefit.

Measure twice, cut once

Quality comes at a cost, so companies need to have confidence that their measures and processes will minimise against loss. For me, successful quality management is synonymous with a successful business, the seven fundamental principles outlined here help a company trust its ability to achieve sustained success – rather than leaving it to serendipity.

Lawrence Baldwin is Head of QHSE at Archer Knight. For more information email Lawrence on lba@archerknight.com

#qualitymanagement #minimiseloss #successfulbusiness

1 min read

Archer Knight Americas business continues to expand

New contract wins for US and Caribbean demonstrate growing global reputation Offshore energy specialist Archer Knight has won two new...

2 min read

We are delighted to announce our role as exclusive financial advisor to Aqueos on sale to Michels

Archer Knight Holdings Limited (Archer Knight), a UK-based energy advisor is delighted to announce their client, Aqueos Corporation (Aqueos), a...

2 min read

Archer Knight Support Well-Safe Solutions On Rig Based Diving Project

Aberdeen headquartered offshore energy services providerArcher Knight (Holdings) Limited, have had the privilege of supporting Well-Safe Solutions...